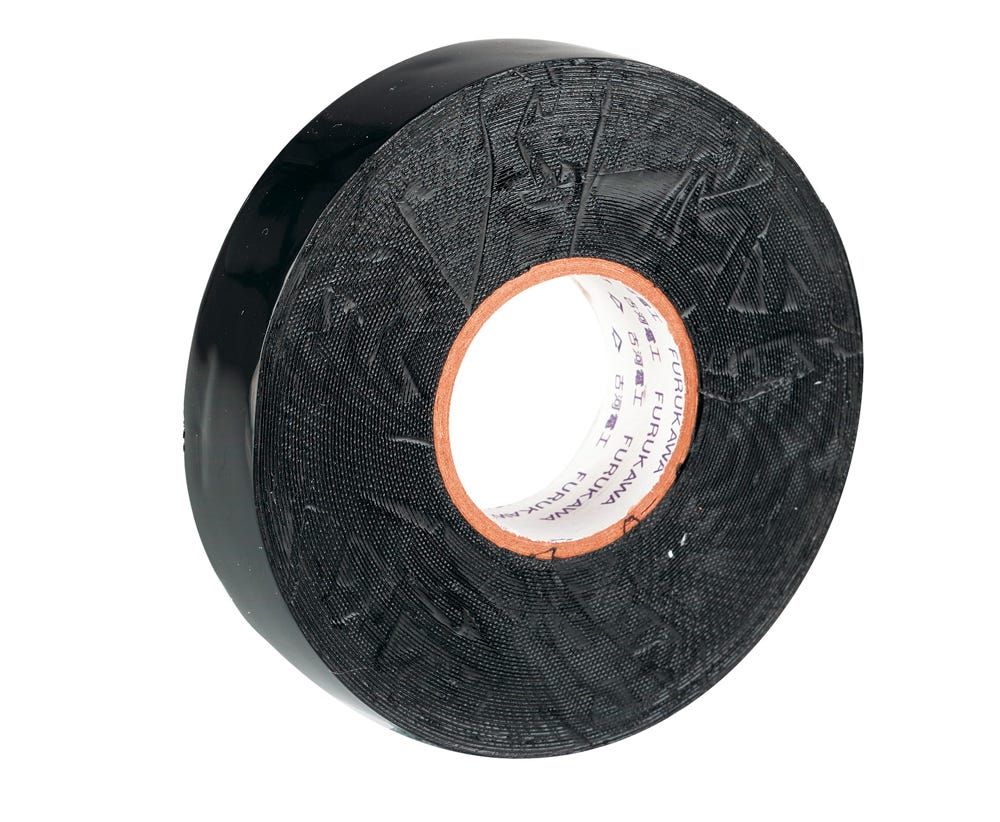

- Highly adhesive synthetic rubber and resin based tape with a polythene separator that forms part of the joint

- Ideal for rugged environments

- Excellent electrical and ageing properties

- High mechanical strength

Product Description

High Mechanical Strength Self Amalgamating Tape is a synthetic rubber and resin with a polyethylene separator that forms part of the joint, giving it high mechanical strength.

High Mechanical Strength - Self Amalgamating Tape Features

- Ideal for rugged environments

- Waterproof, especially if used in conjunction with SAT1

- Excellent electrical and ageing properties

Instructions

When using SAT2 wrap with a 50% overlap with the adhesive side in, and gently stretch so that it closely adheres to the cable. The polyethylene separator forms part of the joint, and as a guide the tape should reduce in width by 1-2 mm when applied. In cold weather warm to room temperature.

Technical Data

Dimensions: 20mm x 10m

Conformant standards

UL, NEMA, IEC, JIS

| Tape Width (mm): | 20 |

|---|---|

| Tape Thickness (mm): | 0.1 |

| Length (M): | 10 |

| Sun Resistant: | Yes |

| VDE Compliant: | No |

| Minimum Temperature (degree celcius): | 45 |

| Maximum Temperature (degree celcius): | 95 |

| Tape Type: | Sealing and Insulation |

| Application: | Insulating, Sealing, Waterproofing |

| Tape Colour: | Black |

| Tape Material: | Synthetic Rubber |

Your ordered quantity for this item is more than what we have in stock.

Stock Availability

| Location | |

|---|---|

Please contact us to know more about this item's availability or possible restock dates.